Journal of Archaeology in the Low Countries 4-1 (October 2012)

Aanloop Molengat – Maritime archaeology and intermediate trade during the Thirty Years’ War[1]

Thijs Maarleveld, Alice Overmeer

Keywords: Texel, Aanloop Molengat, Maritime Archaeology, Photogrammetry, Public Archaeology, Mixed diving teams, 17th Century, Thirty-Years War, Shipbuilding, Dutch-Flush, Transport, Straatvaart, Metals, Mining, Ingots, Cloth Industry, Leather, Pin-making, Nicolaas Witsen.

Abstract

In 1635 or shortly thereafter, a Dutch ship was laden with all sorts of materials and products, mostly metals, but also textiles from the booming wool industries in both Flanders and Holland, a shipment of leather and exotic ivory. It was a ship of considerable size (at least 300 last) and departed from the Dutch Republic at a time of profound troubles. The Eighty Years’ War between the Republic and Spain was far from settled. War at sea was unremitting and intensifying, with Dunkirk privateers an unruly menace to Dutch shipping. Spanish rule in the southern Low Countries was highly militarised, and constant campaigns were waged against it from the North. Central Europe was devastated by the Thirty Years’ War, which had entered a new phase through new alliances. The heavy and strategically valuable cargo of the Dutch ship was assembled from North and South, as well as from a range of places in central Europe. The ship departed for a destination that it never reached. It sank off the coast of Texel, where it was discovered 350 years later.

From 1985 to 1999 the wreck site and finds were subject to archaeological research, producing information on the ship, its setting and historical context as well as on the production and distribution of the individual shipments in the cargo, and informing us about the structure of early modern industry and trade, operating despite and because of the war. The present study, initiated by Wilma Gijsbers in 2010 and supported by the Cultural Heritage Agency of the Netherlands (RCE), the Maritime Archaeology Programme at the University of Southern Denmark (MAP-SDU) and the Netherlands Organisation for Scientific Research (NWO; a one-year Odyssee grant), is the first to bring together all this evidence and evaluate it as a whole. Central to the study is the analysis of the ship and cargo assemblage as excavated, which is presented in Part 2 and 3 of this article. This is combined with an analysis of the discovery, its impact and the efficiency of fieldwork methodology in Part 1, and with reflections on the contribution the project makes to our understanding of production, trade and international relations in the specific historical context in Part 4.

1 The Aanloop Molengat site, research history and techniques

Discovery, impact and preliminary survey

The Aanloop Molengat site was discovered on July 8 1984, 2.5 nautical miles west of the isle of Texel (53° 3.58’ N / 4° 39.30’ E; WGS84), in the approaches (aanloop) to the Molengat gully that leads to the Texel tidal inlet (fig. 1). When the find was reported to the authorities by Texel-based diver, salver and maritime explorer C.J. Eelman, this started a process that proved critical to the development of archaeological heritage management in Dutch waters. Policy development had been ongoing for several years, but in the absence of clarity in the relative applicability of heritage and salvage legislations, finders considered themselves keepers whatever the nature of the find, but all the more so if valuable metals were involved, as in this case. Lavish and intriguing stamps on the lead and tin ingots found in the wreck convinced the discoverers of the unique historical character of their find. It created an opportunity to settle the issue in favour of heritage policies. A decision was taken to conduct a systematic excavation and there was a political decree to stop applying salvage legislation to heritage, and instead to deploy the protective regime of the Dutch Ancient Monuments legislation both at sea and on land (Maarleveld 1993; 2006). The discovery and subsequent fieldwork and research have thus been vital for the development of underwater archaeology in the Netherlands and for the principle of authorised excavations only. Fieldwork was undertaken in close co-operation with the discoverers, whose maritime expertise and equipment were engaged. Local supporters and a large body of volunteers, wide exposure in local and national media, together with local and international exhibitions lent an air of ‘action archaeology’ to the project (Tilley 1989; Sabloff 2008; Carver 2011), which had a significant impact on perceptions of diving and heritage. It was intended as an example.

|

Figure 1 The location of the Aanloop Molengat site in the high-energy zone at the entry of the Texel tidal inlet (drawing: Th. Maarleveld (RCE)).

|

Fieldwork started in July 1985 with a first assessment of the site and the collection of data needed for the further design of the project. This included establishing a provisional rectangular grid of baselines marked by measuring poles at 3 m intervals alongside and 4 m intervals at the ends, recording overall characteristics and dimensions of visible remains, and recording the stratigraphy and the extent of find layers through coring and by excavating a trial trench.

The site and its main characteristics

The site lies in 16 m of water in a dynamic sand-rich offshore area with significant changes in sediment cover. It is a high-energy zone that is subject to annual changes in the coastal slope just outside the ebb-tidal delta of the Texel inlet (Sha 1990). Seas build up easily due to long fetch for all directions between south, west and north-northeast. Nevertheless, the general appearance of the site is that of a consolidated ‘wreck’ mound in the sense of Frost’s (1962) description of amphora sites in the sediment-lean Mediterranean. This is due to the fact that remains rest on a hard glacial till, which they could not sink into and which was resistant to the scouring that normally occurs around a wreck site in a dynamic sandy environment. The ship sits almost upright and the lower hull is kept in place by the heavy cargo, whereas the sides have been destroyed by biological processes. The fact that the top of the wreck mound consisted of lighter cargo material, packages of leather that were only partly abraded and degraded on discovery probably means that the process of site formation has been an intermittent one, interrupted by long intervals of sand cover. It is assumed that the process of abrasion had just restarted when material was caught in trawling nets in 1984 and discovery ensued. It remains unclear how much of the lighter cargo is missing.

The upper works of the ship are absent. Its remains are likely to have spread over a considerable area. No secondary site was discovered in the vicinity. Apart from a number of heavy, cast-iron gun barrels, the excavation produced few artefacts other than cargo material.

The wreck mound extends over approximately 27 x 9 m and is oriented northwest-southeast. The associated find layer extends somewhat further and was eventually examined over an area of 33 x 13 m (fig. 2 HyperLink Drawing. During the first observations, the bales of leather, or rather the smoothly rounded surface of the abraded vertically placed sheets, were conspicuous at the top (fig. 3). They were firmly concreted to a layer of wrought-iron bars running parallel to them below. Immediately southeast of these, but still on the wrought-iron, rested a tier of broken barrels containing rolls of tin. Lead ingots could be observed below the iron bars. To the northwest of the leather packages, but also on top of the iron bars, rows of cases were in evidence through the cubic concretions of their contents, notably cast-iron cannon balls of various sizes.

A geological profile, cored perpendicular to the main axis of the wreck mound, shows a slight depression in the underlying till and a contaminated layer sharply wedging out away from the mound. It extends slightly more to the east than to the exposed west (fig. 4). A metre-wide trial trench excavated to check the extent of the find layer along the southwestern side produced a limited number of small finds. Hand-drawn profiles and descriptions show the top of the till to be irregularly eroded. It dates to the Drenthe phase of the Saalian glaciation (laagpakket van Gieten), also known as the Borkumriff Formation (Laban 1995). The contaminated find layer is well-sorted, with coarse shingle (and small finds) occurring only in its lower part (and pockets) (fig. 5). This is as much a product of natural reworking as of the repeated removal of topsoil before actual excavation could continue.

|

Figure 4 Cross-section on the basis of 1985 observations and coring (drawing: Th. Maarleveld adapted by P. Kleij (RCE)).

|

|

Figure 5 A sketch characterizing the find layer in profile in excavation away from the wreck-mound (from: Dive „report Seweryn 20-07-1991).

|

Logistics, objectives and choice of methods

All on-site work at Aanloop Molengat was characterised by the exposed location close to a lee shore and at two hours’ sailing distance from the nearest harbour. Underwater time was scarce because of the substantial risk of adverse conditions. In view of this, the decision was taken to make the best of the occasional optimal conditions and allow for step-by-step progress in a repeated hit-and-run strategy with a relatively small vessel. This meant accepting slow progress. The approach demanded great flexibility but was realistic in terms of staffing and direct expenditure. It tied in well with the objective of engaging the original discoverers and the local and diving communities, and with using SCUBA as the diving technique. It is a completely different approach than one would choose under time pressure or under development-led circumstances, where it would be appropriate to deploy a large support vessel or platform and be less weather dependent.

With the aim of analysing the packing and stacking of the cargo material, it was considered essential to document the position and orientation of each item in three dimensions. In view of long interruptions to the work, it was not feasible to establish stable, retraceable and reusable reference points on and away from the wreck mound as required for direct survey (Lundin 1973; Adams 1986). Methods of trilateration, or combined measuring and sketching are reliable but time-consuming (Maarleveld 1984). Tidal currents and height differences interfere with direct measuring over distances exceeding a couple of metres. Considering the occasional occurrence of relatively good underwater visibility, it was decided to structure documentation around photography instead. This would fit in well with the hit-and-run operational strategy, and photogrammetry was a developing field that showed great promise (Maarleveld & Vos 1989).

A steel frame of 32 x 11 m was lowered around the wreck mound at the start of the 1986 season (fig. 6). It was oriented along the measuring poles of the 1985 survey and served as an anchor for the shot lines at each corner, as well as for the floating crossbar along which the photogrammetric camera could be moved. The bar was inspired by the system that replaced a photo tower in the Madrague de Giens excavations (Gianfrotta & Pomey 1980), but needed to be much more robust to meet North Sea conditions. Moreover, flashlights were needed and it was decided not to rely on a single-lens camera, but to ensure the creation of a stereo-pair at each shot by using a double-lens camera (Hasselblad/Ocean Optics MC-70).

It was unclear how many layers would need to be recorded and correlated. The depth of the find layer had been established with a handheld Kyholm corer (Nørnberg & Christensen 1980). Probing into the wreck mound was not possible.

Documentation

The vertical photo documentation included temporary reference points and scales and was supported by distance, size and height measurements relative to a datum point, taken with the underwater height meter (UHM) that had recently been developed (Botma & Maarleveld 1987). Although a pilot study (Hugen 1990) showed that a three-dimensional site model can be created from the documentation (fig. 7), the process of photogrammetric processing proved unduly cumbersome (Vos 2011 HyperlinkVOS). Even on land and in clear water, photogrammetry is not necessarily the most cost-effective documentation method (Reinders 1986). With software that integrates various ways of data capture and 3D modelling, it adds to the archaeological toolkit but is hardly ever a replacement (Green & Gainsford 2003; Sanders 2011). The main problem is that even in non-parametric approaches the accuracy of automated results is fully dependent on the accuracy of the input and the input that qualifies as archaeological documentation needs selective and consistent, time-consuming interpretation. Part of the disappointment with photogrammetry was that the amount of time, equipment and computer power needed for processing was not cost-effective and that outsourcing interpretative phases led to faulty interpretations.

From the start, the vertical photographic pairs were complemented with oblique photographs of each individual cargo item to be removed. Individual items were identified on vertical photographs according to the imaginary grid. This obviously was done on land and in order to reduce precious bottom time. A label and a labelled photo assignment for one or more oblique shots of the same item were then prepared along with a slate with its sketched position, to be taken down on the next occasion. Assignments to remove and lift an object followed, similarly with an identification sketch on a slate (fig. 8).

|

Figure 8 A typical sketch informing the order of removal in excavation (from: Dive report Vos 22-07-1992).

|

The find number of each object relates to the first photograph on which it appears. Although in principle this allows for quick reference, it leads to a complicated numbering system, the more so since more photographs were needed for full coverage than anticipated. Also, it was a challenge to keep track of each item’s correct number. A simpler serial numbering system would have been advisable. Such a simple system was effectively used in the registration of small finds that were collected when excavating the find layers away from the wreck mound, both in the 1985 trial trench and in the south and eastern sides, where finds were collected in approx. 2 x 2 m squares (sections A to M, see Hyperlink Drawing).

Organisation, safety and technical issues

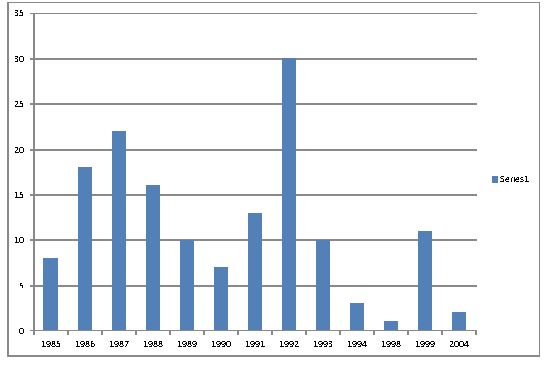

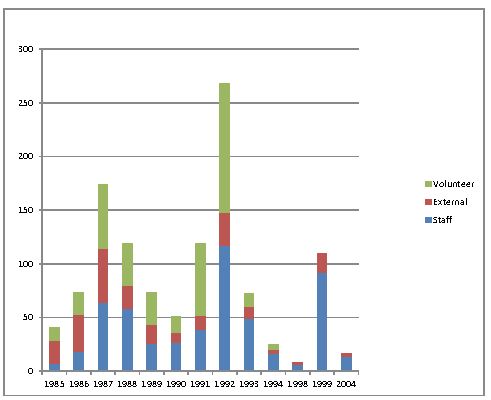

The hit-and-run project ran in tandem with the excavation of the 16th-century merchantman Scheurrak SO 1 (Daalder et al. 1998; Manders 2003) under the assumption that activities offshore could be combined effectively with activities in the Wadden Sea during 14-week summer campaigns out of a fieldwork base on Texel. But calm weather is also required for excavating in the Wadden Sea. The most productive Aanloop Molengat seasons were 1987 and 1992, with 22 and 30 days of work on site. Apart from monitoring missions in 1998 and 2004, work on site was interrupted in 1994, only to be resumed for a two-week campaign in 1999, when a dedicated professional team had been made available (Chart 1). All earlier seasons involved a mixed team, including a gradually increasing core of professional diving archaeologists, a decreasing number of locally hired maritime service personnel and a large number of volunteers, mostly archaeology students and avocational archaeologists – more than a hundred people in total (Chart 2).

Chart 1 Fielddays per season.

Chart 2 Fieldwork man-days per season divided according to staff category. A total of 102 persons took part in the fieldwork operations, spending a total of 1141 man-days on site. 80 % (921 man-days), however, was realized by a core of 28 persons, who each worked more than 10 days on site. 15 of these were employed as staff, 4 were external, each of them engaged from the local maritime community and the 9 others were persevering volunteers.

The frame and its deployment were a solid investment, but proved immensely useful. It served to delimit the site and to provide orientation and a safe and stable working environment in an area with shifting sands and varying surface cover. The camera-navigation bar proved a cumbersome piece of equipment. It needed at least a full diving day to install or remove at the beginning or end of the season. Despite its robustness, it was still subject to swell. It needed a lot of air in its floats to keep it stable, which meant heavy work on the winches to move it around. It was the sort of equipment that assumes priority rather than enabling more important work (Keith 1990). Twice, after a storm, it went missing and was replaced by a balanced, single-diver-operated support for camera and flashlights. A well-trimmed diver obtained the same results with the two-lens camera, with far less trouble. Swell was still a problem, but a running current actually had a stabilising effect.

A safety booth was fitted to the frame, inspired by the ‘telephone booth’ of the Yassi Ada excavations (Bass 1968) (see fig. 6). As diving was organised in untendered SCUBA, it was considered an extra support. Although a fixed feature, it was missing when the site was relocated in 1987. Despite heavy welding and bolts, it had been torn from the frame by a trawl net. It is unclear how much the frame moved accordingly, if at all. Damage to the archaeological material seemed very limited. The booth was not replaced. A spare cylinder- or surface-supplied regulator took its place until a system of through-water communication was implemented for the team. The central safety measure was a strict procedure of planning, checks and monitoring of the diving operation.

It was not just the removal of backfill and overburden of sand, but also the cutting away and removing of heavy netting and other alien material that distracted from archaeological work.[2] The hit-and-run strategy was unsatisfactory for these essential activities. The small support vessel Phileas Fogg did not have adequate dredging and lifting equipment, and valuable time was lost as a result. At a particularly critical moment in 1991 it was therefore decided to call on the assistance of the Terschelling-based Duikteam Ecuador and their well-tried diving vessel Ursus II, which had stronger equipment and a compressor.

Progress, consistency and an integrated site plan

Conditions were hardly ever as initially expected and support activities such as technical preparation and cleaning before a photo-documentation run took up almost as much bottom time as reference measuring, setting up temporary data points, excavation, and recording, labelling and removal of find material (Chart 3). Data gathering spanned a period of nearly fifteen years but the total time spent on-site at the bottom surface remained limited to slightly less than 970 hours, the equivalent of what a team of six can achieve on a landsite in a four-week campaign.

Chart 3 Bottom minutes per season according to category of activity. Of a grand total of 58170 bottom minutes, 27902 were used in supportive and technical activities, whereas 30268 minutes were used directly in excavation and data gathering. Recording made up for 9834 minutes in total.

It was only after the 1988 season that the first layer was removed. The excavation of find layers adjoining the wreck mound began simultaneously, producing sketches, profiles and small finds that added to the variety of the assemblage. During the 1991 season, disappointing visibility conditions and a sand dune on part of the site led to a reconsideration of the documentation strategy (Briefing report 12 July 1991). Interestingly, this was almost exactly halfway (455 hours had been spent underwater, with another 515 to come). It was decided to remain true to the original recording strategy after the calculation that switching to conventional documentation in sketches or trilateration would take another 400 underwater hours of expert recording, a luxury that could not be afforded, even though more expert staff were available than at the start. In the end, expert recording accounted for only 164 underwater hours in total. Nevertheless, it took until the productive season of 1992 before a second layer could be documented vertically in full. Most of the subsequent removal and lifting of cargo material was finished when the project was discontinued in 1994. The excavation of the southeastern side was finalised in 1999. Although the fieldwork took far longer than the five seasons originally planned, it stayed within the original project design and budget.

In hindsight, the photographic record proves well up to the questions to be resolved. There is enough redundancy in verticals and obliques, and with modern computers and software it has been relatively easy to join the verticals in a 2D mosaic (fig. 9). A more elaborate site plan was prepared independently of this, integrating all types of data gathered in photographs, sketches and direct measurements (see fig. 2). The aim to integrate all observations in a three-dimensional model was abandoned in favour of achieving this result, but it would still be possible to create one if sufficient reason arises.

2 The Aanloop Molengat ship

Ship construction and internal organisation

The Aanloop Molengat investigation placed greater emphasis on the cargo than on the ship itself. Nevertheless, quite a few characteristics of the ship can be deduced. It sits more-or-less upright and the superstructure is missing. The composition of the find assemblage suggests that large parts broke away and were not deposited on site. Only heavy cannon were left behind, eleven in all. The lower hull is kept in place and hidden from view by the cargo mound, notably the concreted mass of iron. In consequence of the decision not to move or remove this, all observations relating to the ship’s construction have been made along the wreck mound’s sides. The lower hull extends over a length of 26.5 m and seems to be continuous and relatively straight. It is approximately 8 m wide. Observations at the northwestern end suggest that it has a slight list to the northeast, and that it may have broken lengthwise along the keel. This would explain the wide lengthwise crack in the mass of closely packed iron bars.

The keel is a solid beam of oak. At the northwestern end it protrudes some 3.4 m from the cargo, where it ends in a vertical scarf. At the other end, it could not be identified. It must, however, have extended over the full 26.5 m. At the broadest point observed, where it was cut for a dendrochronology sample, it is 44 cm wide. It is almost square, with a depth of 41.5 cm. It tapers towards the end where it still has a depth of 38 cm and is likely to widen in the other direction. To receive the garboards, a single rabbet has been cut on either side, at 5 to 6 cm below the top and rising forwards (fig. 10). A single square nail hole indicates that the garboard had been attached with square nails. Rows of two or three nail holes, spaced at about 13 to 17 cm intervals, occur on the sides, but have not been observed underneath. The nail holes are thought to reflect a layer of sheathing, probably in lightwood, as no metal has been observed. The end scarf is 33 cm long. One iron bolt and two iron spikes secured it to another construction element. In view of the tapering end and the rising rabbet, this could hardly have been another length of keel. Neither is it a plausible solution for joining sternpost and keel. The scarf, which faithfully matches Witsen’s (1671, 147-151) description of a stem scarf, almost certainly joined an apron or lower stem section. This implies that the northwest end of the wreck is the bow.

Following from the identification of the ship’s orientation, it can be inferred that the sternpost and deadwood broke away, taking some length of keel with them and breaking it loose in such a way that it is now missing from the otherwise fairly contiguous shell of bottom planking. Despite the list to the northeast, the southwestern (or port) side of the ship is best preserved. The sea bottom is highest here and amidships the ship’s side is continuous to include part of the turn of the bilge.

At the northwest or fore end, six (or seven) adjoining hull planks are observed, all ending in abrasion. They do not directly adjoin the keel. Either the garboard strake is missing or the keel has shifted at this end. The planks have widths of 25 to 44 cm. At the southeast or aft end, thirteen hull planks protrude from under the cargo. At the portside, two of them end in a scarf joint that is more than 60 cm long. The orientation of these scarves does not affect the interpretation that this is the stern. Plank widths vary from 28 to 38 cm. Their thickness has not been systematically recorded, but is at least 7 or 8 cm. It seems to be a bit more in the bilge along the side. The planks are flush; it is a carvel hull. Wood of a lighter colour has been observed on the outside of the longest hull plank aft. It is approximately 25 cm wide and may well be part of lightwood sheathing, such as is also inferred for the keel. Otherwise, all planks and timbers seem to be oak.

Transverse timbers are visible at the southwest edge (port side) where erosion has produced a smooth cut through the hull structure and where they stand together, almost without any spaces (fig. 11). Other frame timbers are visible at the northeast or starboard side, where alternating timbers have broken away. Room-and-space is irregular, but seems to average around 40 to 45 cm. Sided dimensions of the timbers vary from 14 to 25 cm, with an average of 19 cm, which is also approximately their moulded dimension. Some of the timbers have original endings, others continue in a sharp curvature. Although the alternating timbers are placed closely together in the bilge, no indications for interconnection have been observed.

|

Figure 11 Planking, frame timbers, ceiling and the rim of the concreted cargo along the southwest side of the wreck-mound (photo: P. Stassen (RCE)).

|

Internal structural planking was attached to the inside of the timbers. The widths of these ceiling planks vary from 33 to 50 cm. Their thickness is unknown, but apparently similar to the planking. They are flush-laid without any spaces, providing a closed ceiling, fastened with treenails of 3 to 3.5 cm in diameter.

In the sandwich of planking, timbers and ceiling, the timbers are relatively light. Their dimensions and spacing (17 to 18 elements at the bilge over 4 m of ship’s length) compare well with what we know of early modern merchant ships that are built shell-first in the Dutch-flush manner (Maarleveld 1984, 67; Maarleveld et al. 1994; Lemée 2006). Although this ship is larger than other examples, framing is not more substantial, and planks and ceiling may be slightly thicker (only B&W2 compares well in that respect; Lemée 2006, 200ff.).

The dendrochronology of the keel suggests that it came from Westphalia, a region in northwest Germany, roughly between the rivers Rhine and Weser (Jansma & Spoor 1991). This is consistent with a building spot in the Northern Netherlands, where practically all timber was imported, but it could of course point to northern Germany as well.

A striking issue is the absence of a clear indication for the presence and position of a mast. The mainmast cannot have been positioned where the wrought-iron bars lie. Close scrutiny of the site plan (see fig. 2) shows that the forward portion of concreted iron ends in a straight line at right angles amidships. This is most obvious between metres 14 and 15 on starboard. The straight line is likely to reflect the original presence of a bulkhead, behind which the mast was stepped, in an area that is characterised by a jumble of concreted cannon balls that have filled the empty space where the mast once stood. It might even be the case that the wrought-iron is not continuous, but leaves a cross-ship corridor of about one metre unoccupied. To what extent this would affect the indicative calculations of cargo weight remains to be seen. If a corridor is present it seems to be filled with cannon balls, perhaps in cases, and cast-iron is only fractionally lighter than wrought-iron or steel.

Apart from the inferred bulkhead amidships, which may have been a temporary structure, a bulkhead seems to have been present at the forward end of the iron bars. After all, here the bars end in a more or less straight line as well, possibly with some shifting forward in the middle. At the aft end, just below the barrels of tin, the very residual remains of a decayed bulkhead have actually been observed. The overall length of the hold between these two bulkheads was 19.5 m. The depth of hold cannot be inferred. Apart from the cannon, no remains or evidence on the orlop and upper structure was found on site.

Reasoning from the coherent structure as shown in fig. 2, the ship can hardly have been narrower than 8.5 to 9 m. To the preserved length of 26.5, one should add some 7 m or more for apron and stem. Moreover, a substantial part of the stern is missing. How much depends on the presence and form of a transom. The bottom is still wide at the aft end, but individual strakes are not, which might indicate that the hull narrows at this point. Nevertheless, it would be hard to fit the continuing hull, deadwood, sternpost and rudder in less than 3 m. The overall length cannot have been less than about 37 m. Another approximation of size is its cargo capacity. Even though the ship sank, it is not reasonable to estimate its capacity at less than the total weight of the goods it carried. The absolute minimum weight of the cargo as found is estimated at 550 tons, while more than 600 tons is more likely.

Armament and inventory

Eleven cast-iron cannon have been found across the wreck. Two of them were lying directly aft of the south end of the wrought-iron. Four cannon were scattered along the starboard side. Five others were lying in the south of the site (see fig. 2). The distribution of the cannon implies that they were used as ship’s armament, rather than being part of a cargo of new cannon, or damaged gun barrels, as in the Brouwerhavense Gat 2 wreck (Vos 2004). They probably tumbled down from their original position on a higher deck during the wreck formation processes.

The two cannon directly aft of the wrought-iron were recovered in 1988. They had been moved to facilitate excavation and were lifted in order to check for markings. After weighing (both 1280 kg), they were drawn at a 1:5 scale and studied by Nico Brinck, an expert in armament (fig. 12). The cannon are 9-pounders, large cannon used for large ships. They are semi-culverines, with tapered trunnions and a bore of 11 cm. Such cannon are believed to have been cast in England and to be typical of the 1630s. In view of the dimensions, there must have been more 9-pounders or even heavier armament aboard.

|

Figure 12 Two identical cannon were recovered from the Aanloop Molengat wrecksite (AM-2/3.01.2.1 and AM-3/4.01.2.1). Each is approximately 2.46 m long (drawing: N. Brinck).

|

Many cast-iron cannon balls of various sizes were lying approximately amidships, concreted in two rows of cubic shapes. A bar shot and a grenade, with the powder charge still intact, seem to be exceptions in the assemblage of these ‘normal’ cannon balls which belonged to the cargo rather than to the armament (van der Linden forthcoming).

A total of 1558 lead balls were recovered among the small finds in the southeastern end of the excavation. They range in diameter from 8 to 18 mm, but two distinct groups of 10 and 15-16 mm are discernible, the smaller ones for pistols, the larger ones for muskets (van der Linden forthcoming). All musket and pistol balls were measured using XRF. The results show that no homogeneous groups can be discerned. The composition is very different from that of the lead ingots in the cargo. This implies that the musket shot was made by smelting scrap lead and re-used shot, probably over and over again. It is unlikely to have been a commodity for trade; rather, we are dealing with ammunition supplies on board this ship (van der Linden forthcoming). As the vast majority (86% of the 847 for which the findspot is documented) came from sections C and H, it can be inferred that they had been stored in the stern along the ship’s centreline, rather than in the hold. This is consistent with the layout of most early modern ships, where ammunition and hand weapons were stored in central lockable compartments aft. Witsen (1671, 58-59, 159, 198) describes this for contemporary ships, for ships of 30 years previously, and for ships from France.

Strikingly few objects belonging to the ship’s inventory have been recovered. No earthenware or stoneware can be associated with the wreck. All such finds are clearly from a different period and are dealt with below as later contamination. The few items that are likely to belong to the ship’s inventory originate from a thin spread all over the excavation area.[3] A few fragmentary wrought-iron fittings may be part of the rigging. The only possible item of navigation equipment is a small sounding lead. The conical lead has a length of 9.5 cm and a maximum width of 4.5 cm. Its base is not hollowed and we cannot rule out that it is a large fishing weight that should be considered a later intrusion. Similarly, two pieces of rolled lead sheet, 24-25 cm long and 1.6 cm in diameter, may be interpreted either as weights, or as belonging to the original ship’s equipment.

Gear for cooking, eating and drinking is highly underrepresented. One pewter spoon was found in section F. It has a circular bowl and a crowned Tudor rose mark with initials CH near the hexagonal handle. The Tudor rose appeared in the Northern Low Countries from about 1540 onwards (Dubbe 1965, 69). Cast-iron fragments seem to indicate at least three three-legged cooking pots.

Two complete pewter plates and two small fragments of a plate were found in sections F, H and M. The plates have a diameter of 22 and 22.5 cm and a rim of 4 cm. No tin marks are visible.

The pestle of a mortar was found in section B (fig. 13). The pestle is made of copper or bronze, is very heavy, and has a length of 25 cm. It has pounding surfaces at both ends, separated by a ridge. One end is somewhat longer than the other (12.5 cm/11.5 cm), so the pestle can be used by both large and small hands. Mortar and pestle are used by apothecaries and pharmacists to grind and pound hard spices and substances for drug preparations. The accompanying mortar has not been found in the wreck.

The function of two almost identical objects is unclear. The objects of 5.5 and 8.5 cm in length are made of copper and have a screw thread at one end (fig. 14).

|

Figure 14 Two unidentified copper objects with screw thread ends. Length 5.5 and 8.5 cm respectively (photo: T.Penders (RCE)). |

Later intrusions

Apart from the ship’s equipment, armament and inventory, as well as the extensive cargo that will be discussed in Part III, some intrusive material was found. It consists of the inevitable net weights in all shapes and sizes, eleven sherds of recent glass and one small glass bottle, nine sherds of recent white and red earthenware and stoneware, a single brick, three bones and a recent yellow metal cringle. All these unrelated artefacts were found in excavation in the southeast area.

3 The Aanloop Molengat cargo

Introduction

The nature of the cargo was a decisive factor in the decision to systematically excavate and research the Aanloop Molengat site. It has remained the focus throughout the project. From the start a range of find categories has been subject to specialist research and interim reports. (HyperlinkIntRep) The present study is a synthesis of these and new studies, undertaken in conjunction with archiving the assemblage in the National Depot for Ship Archaeology and integration of the documentation in the e-depot for Dutch archaeology (EDNA). In all, over 3000 objects have been raised, under 1184 individual find numbers. The assemblage will be discussed category by category, starting with the heavy shipments and approximately following the stowage plan.

Lead in rough ingots

Lead ingots have been found at the southeastern end of the site, which is the aft end of the ship. The ingots had carefully been stowed in a single layer directly on top of the ceiling planks (fig. 15). Many rested in their stowing position, with wrought-iron staves on top. Others were found to be lying in the sand, but their pattern of stowage is still recognisable. In total, 167 ingots have been recovered in excavation. (HyperLinkIngots) Three others are known to be held by a local diver; in total more than 200 have been observed.

|

Figure 15 The wegde-shaped and angular ingots were carefully stowed in a single layer in the depth of the hold, directly on top of the ceiling (photo: P. Stassen (RCE)).

|

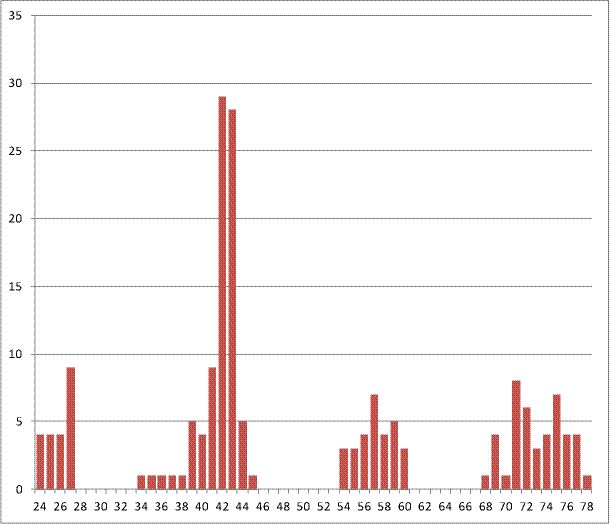

The excavated ingots are wedge-shaped or roughly angular (fig. 16). They are about 24 to 33 cm long and wide and 11 to 23 cm thick (av. 17 cm). They vary between 57 and 156 kg in weight, with a total weight of 16851.5 kg (n=165) (Chart 4). Most ingots fall into the range 90-120 kg, and the average is 102.1 kg. The investigated ingots represent a considerable part of the original shipment. If ingots are packed under the full extent of cemented iron bars that remain in situ, the excavated sample would be more than 30%. This is unlikely, however. Nevertheless, it is highly probable that the layer extends right up to the northwestern-most observation (between datum points 22 and 27). In that case it is unlikely that the sample represents much less than 50%. The total weight of the shipment is estimated to be in the range of 30 to 50 tons.

Chart 4 Weight distribution of the lead ingots.

All ingots have smooth upper faces and rough bottom faces, suggesting they were made in a mould, dug out in the sand (Voormolen 1992, 20). The proportion of the wedge-shaped ones to the angular ones is 148 to 22 (n=170), which means that on average one rectangle occurs for every 6.7 wedges. Although this would mean that the angular ingots are strongly underrepresented in the sample, it seems likely that the lead was cast in an oval-shaped mould, after which the master ingot was cut into six parts (fig. 17) (Voormolen 1992, 21). The sides are smooth and do not display cutting marks.

Some ingots, both wedge-shaped and rectangular, have been incised, causing one corner to protrude (see fig. 16). The ingots with a notch occur in the proportion of 34 to 136 (n=170), which means one notched ingot to four regular ingots, suggesting that only one notch was applied to a master ingot (Chart 5). The notch was probably used to remove the master ingot of about 600 kg from the mould (Voormolen 1992, 22).

Chart 5 Distribution of the four different shapes of the lead ingots.

Invariably, the ingots display a number of small square dents, ending in a point. These are the marks of hooks or lifting thongs, used for handling the ingots (Voormolen 1992, 29). Moreover, the ingots are freely struck with 17 different stamps (fig. 18). Only one stamp (A) is found on every single ingot, mostly more than once, up to a maximum of 43 times. It looks like a monogram of the letters T and C. An almost identical stamp was found on ingots in a Dutch ship built around AD 1531-1533 (Azier 2007, 79). It is uncertain whether it refers to a trading house or to quality. There seems to be no correlation between the weight and the type of stamps on an ingot. After A, the most frequent stamps are B (75 x) and E (49 x). All other stamps occur two to eight times. The wedge-shaped ingots with a notch have the largest variety of stamps, up to six different ones. As stamps occur on all surfaces including the sides, at least some of them were applied after the master ingot was divided into parts. Most marks seem to be merchants’ marks, of which thousands were in circulation in the 17th century. They may refer to a producer, trader, or merchant house (Kits Nieuwenkamp 1955).

Mark I is a cartouche with a Maltese cross; mark J is similarly designed but it is unclear what it depicts. Mark P is also a cartouche and displays a crowned eagle. These cartouches have a heraldic touch and may refer to the area and organisation of production. This is further corroborated by stamp E, which is a rectangular cartouche with the capitals ILKUS, a spelling variant of ‘Olkusz’, a town in Lesser Poland.[4] From the end of the 16th to the beginning of the 18th century, Olkusz was by far the most important lead-producing centre in Poland (Molenda 1963, 1972). Isotopic analysis, in which the composition of 14 ingots was compared with 12 samples of galena (the natural mineral form of lead sulphide, the most important lead ore mineral) from the lead-zinc-silver mines of the Olkusz region, supports this identification (Clayton et al. 2002, 303 & 307; table 2). The normal pattern of the Olkusz trade was from Krakau (Kraków) along the Vistula to Danzig (Gdánsk) on the Baltic (Molenda 2001, 88ff.).

The Aanloop Molengat type of ingot is not previously known from literature and does not figure in Willies’ (1982) typology. Similar, but not identical, are two ingots found off Cape Arkona in the Baltic (Förster 1994, 59). The Aanloop Molengat finds enabled Molenda (2001, 22-23) to correlate with a single ingot find from medieval Novgorod and to explain the variety of master ingots and their partitioning into four or six sections (secatio plumbi, in the sources). The average weight of the Aanloop Molengat master ingots of about 600 kg corresponds to ten centner (hundredweight). This correlates well with the information from which time series of production were derived, but 6, 8 or 12 hundredweight casts were apparently also applied. The notches are indeed explained as primarily for tackling and handling the master ingots. Interestingly, Molenda mentions the strategic quality of lead and prohibitions on its export during periods of war (Molenda 2001, 36). Evidently, exceptions drove production as well as trade.

A recent find on the coast of Namibia, the Oranjemund shipwreck cargo, includes a shipment of lead that appears to be very similar to the Aanloop Molengat assemblage. The published photograph seems to display both wedge-shaped and rectangular ingots with and without incisions. Their weight varies between 70 and 156 kg (Chirikure et al. 2010). Although stamps and seals are mentioned, only one unidentified seal is published. The assemblage is thought to predate Aanloop Molengat by a hundred years. A study of the stamps and isotopic composition may clarify whether it comes from the same source. Considering the ingot type, it is probable that the Oranjemund shipment, like the ingots of Aanloop Molengat, represents primary production. It is tempting to suggest that it was produced in Lesser Poland.

Iron in bars

Wrought-iron bars make up a large part of the cargo. Although oxidation is limited, the bars are cemented together in a continuous concretion (fig. 19). The bulk is 17.0 m long and varies between 6.30 and 7.50 m in width. At the southeastern end it has a central extension of 3.35 m, which is only 1.70 to 2.60 m wide. The pack is 30 to 60 cm thick along its sides. Several fissures occur in the concretion, notably a large lengthwise crack and a crack at right angles midways. Although the cracks may reflect some discontinuities in packing, they were specifically inspected for evidence of bundling in batches. As no such bundling has been observed, the breaks apparently occurred during the formation of the wreck site. No bars are folded as in the cargo of the Gresham Ship of half a century earlier (Auer & Firth 2007). The bars are tightly packed. The total weight of the shipment is estimated at more than 500 tons.[5]

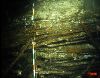

Most bars are rectangular in cross-section, 6 cm wide and 1.5-2 cm thick. Some are square with dimensions of 3.5 x 3.5 cm. Individual bars are at least 2.5 to 3.5 m long. The excavation did not interfere with the consolidated and concreted mass of this part of the cargo. Only eleven loose-lying bars were recovered. Samples show that the iron is in excellent condition (fig. 20). No marks were found on them.

|

Figure 20 A section of an iron bar shows the metal to be of excellent quality and preservation (photo: A. Overmeer (RCE)). |

In order to define production and determine or exclude provenance, a sample was taken of iron bar AM-1999-73 for metallurgical analysis by Joosten & Nienhuis (2012hyperlinkJ&N). Iron and slag inclusions were analysed by energy-dispersive X-ray analysis (EDX, ThermoScientific, NSS) in a scanning electron microscope (SEM, JSM5910LV). Carbon content is 0.7% of the weight, which is appropriate for wrought-iron. The iron contains around 1% of small slag inclusions that are aligned as a result of folding during forging. The core of the sample is ferrite; the cover is steel. This might indicate that the wrought-iron is carbon-enriched in a specialised furnace (Tylecote 1992). Most of the inclusions consist of one phase, fayalite, a glass low in iron and high in calcium, wüstite or quartz. Some inclusions consist of two phases, mainly fayalite and glass. The ratio between SiO2/Al2O3 indicates that some inclusions derive from additions, i.e. sand, during the post-smelting phase. In plotting the major element composition of the rest of the inclusions in a diagram distinguishing the direct from the indirect processes (Dillmann et al. 2007), it is shown that they most probably derive from the direct process. The low manganese and phosphorus content of the inclusions excludes production from high manganese and phosphorus ores.

Iron was produced in the Low Countries, but not on a scale to assume wholesale export; rather, it was imports from Sweden that satisfied the demand (Kuiper 2006, 65; Gawronski 1996, 281). The provenance of the wrought-iron bars might effectively be Sweden, which is known for exporting low-phosphorus steel in the period (Pleiner 2000). Witsen (1671, 119) discusses iron bars, their markings and relative qualities and refers to ‘steel’ from Nuremberg as being 10% more valuable than ‘Swedish steel’. Present research does not permit a final characterisation. No markings have been identified and the relative manganese and phosphor content of ores exploited in the 17th century, including those from Sweden and Bavaria, has not been studied comprehensively. Archaeological parallels are few. The bars in the ‘Gresham ship’ of the outgoing 16th century (Auer & Firth 2007) derive – at least partly – from a manganese-rich and therefore different source (Birch 2010; Birch & Martinón-Torres forthcoming). An adequate comparison for the 17th century is BZN2/BZN15 (Vos 2012), whereas the Hollandia and the Sophia Albertina provide similar material for the 18th century (Gawronski 1996; Overmeer 2012).

Tin in rolls, packed in barrels

At the southeastern end, a tier of spruce barrels was stacked on top of the wrought-iron bars. These barrels had broken up and their contents had been dispersed, but their bases and some of their contents were still found in their original position at the top of the wreck mound (fig. 21). The barrels contained tin in a typical form of roughly cast sheets, rolled in a rough cylinder, approximately 40 cm long (fig. 22). The weight of the rolls varies considerably and is 4.727 kg on average. Some rolls are preserved in excellent condition, others have decayed and eroded. In total 1514 kg of tin has been excavated, deriving from a minimum number of 359 rolls. An interesting bonus is a few pieces that can be interpreted as quality samples (fig. 23) rather than ordinary production (cf. Reinheckel 2002, 29). The total weight of the shipment, including barrels, must have been at least two tons.

|

Figure 22 A typical roll of tin (AM-7.8.3) with marks from Horní Blatná, length 42 cm, weight 4210 g (photo: T. Penders (RCE)).

|

The sheets generally have three marks, applied with a die in a molten appliqué. Twenty-four different dies have been identified (HyperlinkTerhorst). The images include a range of heraldic symbols, years, monograms and words in German, for instance: ‘SEIFFEN*ZIN*VON*DER*PLATEN’. In 1988, the general provenance and probable quality (‘Drei-Zeichen-Zinn’) was established with the help of the Sektion Bergbauforschung des Kulturbundes der DDR, Ortsgruppe Seiffen. ‘Seiffen’ does not refer to the town in Saxony, but ‘Platen’ refers to Horní Blatná on the southern flank of the Erzgebirge/Krušné Hory (Ore Mountains), in the present-day Czech Republic, which was called ‘Platten’ under Bohemian rule. Vítězslav Bartoš (1994), a local historian from the city of Karlovy Vary, correlated the marks with individual mines. Besides the mines of Platten/Horní Blatná, these include the mines of nearby Seifen/Rýžovna, Hengst(er)erben/Hřebečná and Gottesgab/Boží Dar. A smaller portion derives from Eibenstock in Saxony on the northern flank of the Erzgebirge. As five more dies have been recognised since 1994, some tin may derive from other locations that have not been identified.

|

Figure 24 Seifen extraction pits and waste dumps near Horní Blatná (photo: Th. Maarleveld, Oct. 1989 (RCE)).

|

In the Erzgebirge, tin ore (cassiterite) was primarily extracted from Seifen, a term that refers to alluvial placer deposits (fig. 24). Water was used extensively to sort and rinse the ore. It is the simplest method of extraction and produces the purest ore. Subsurface mining only took place once alluvial deposits were exhausted (Hedges 1964, 13). Operations in the Erzgebirge are extensively and analytically described by Georgius Agricola (1556) (fig. 25), who lived in Annaberg in Saxony and had first-hand knowledge of the works. He does not specifically refer to Horní Blatná, but mentions nearby Joachimsthal/Jachymow. Tin from contaminated ore was usually cast in bun ingots that could be smelted for further refining. This was unnecessary for Seifenzinn: . . . ‘if the metal is pure, it is poured immediately upon thick copper plates, at first in straight lines and then transversely over these to make a lattice’ (Agricola 1556, book IX; transl. Hoover & Hoover 1950, 414). An experienced smelter could separate any contaminations immediately and the quality was tested visually while pouring (pers.comm. Dr Christoph Bartels, 2011). Unrolled sheets from Aanloop Molengat reflect the lattice pattern that Agricola describes (fig. 26). After a sheet was rolled with a wooden mallet, each roll was impressed with an iron die. According to Agricola, low-quality tin had one mark, while Seifenzinn had two. The rolls from Eibenstock reflect this. The rolls from the Bohemian production centres all have three marks: two regional denominations, patented by the crown,[6] and a producer’s mark (HyperlinkComb). Although the third mark was probably introduced to suggest even better quality, and although that suggestion is attractive to Bartoš (1994, 2), analysis with XRF shows a tin content of more than 99% for Bohemian and Saxon products alike (HyperlinkXRF). This high quality means that the metal could be used for many alloys and purposes, including high-quality cannon bronze and pewter finewares (Kellenbenz 1987; Dubbe 1978).

|

Figure 25 Plates from Agricola's De Re Metallica of 1556. From left to right, a: seifen extraction and washing in a diverted stream, book VII; b: pooring fluid tin on a thick copper plate in a lattice pattren; c: the lattice sheets are rolled with a wooden mallet, book IX (from:

Hoover&Hoover 1950

, 337, 415, 418).

|

The stamps feature dates in the range from 1556 to 1630. Evidently they refer to the dates when the patent was established or the trading and production house was founded and the die was made. It is likely that the tin was produced shortly after 1630. As a result of the Thirty Years’ War (1618-1648), production in the area had fallen considerably, but Aanloop Molengat shows that it still had its share of the international market (Kellenbenz 1987). Despite the war that profoundly affected the region in those years, it is likely that the tin was collected in the staples of Nuremberg or Leipzig, where the important entrepreneurs in the German tin trade were established. Prices had risen steeply in response to armament demand (Bartoš 1994). The Peace of Prague (30 May 1635) may have been a good occasion to resume trade, but the Main-Rhine route through to Amsterdam was frequently blocked and continued to be impeded after the blockades of 1634-1635 (Haller von Hallerstein 1975, 63; Israel 1980, 473-475). It is therefore likely that the Elbe route through Hamburg was followed. The fact that this route was not uncommon is illustrated by a decree of 1613 establishing the wages of skippers transporting ‘tin in barrels’ from Hamburg to Amsterdam (van Dillen 1929, 44-47). A source relating to a dispute on tin quality involving Leiden tinsmiths refers to Hengst(erben) as one of the sources of tin in rolls (Anon. 1592). At what point en route the rolls were packed in barrels is unclear. It cannot have been at the site of production. Several assemblages of rolls were found in close association, either with the remains of their barrel or cemented together. Not all rolls in these assemblages had the same marks. They must have been packed at a middleman’s or conveyor’s entrepôt. With 70 to 90 rolls in each barrel, we are dealing with a shipment of four, five or six barrels in total.

|

Figure 26 An unrolled sheet (AM-2/3.01.2.4.16) clearly shows that fluid tin was poured on a (copper) plate in the way Agricola describes. The sheet measures 40 x 70 cm (photo: T. Penders (RCE)).

|

Bovine hides, in bales

Adjoining the tin barrels, bales of leather were stacked in a cross-ships tier on top of the wrought-iron bars, with a few wooden stakes in between (Blok forthcoming). Two bales were found in their stowage position. One bale was found off the wreck mound. The bales had been stowed lengthwise on their sides, with the hides vertically. The hides in all three bales were smoothly abraded along the top, indicating that they had been exposed for some time and that the third bale had only recently broken away (see fig. 3). For the central bale, abrasion is very limited, thus allowing the composition and folding to be analysed. Each bale originally measured 180 x 150 x 80 cm and was packed in matting (figs.27 and 28). The hides were tanned and were all bovine. Two hides, sometimes joined with a string, were folded together to form a bundle (fig. 29) (Kleij 1992b, 18-22). Each bale contained 60-65 bundles, approximately 375 hides in all. The density of leather is approximately 945 kg/m3, so the three bales would have weighed little less than two tons.

|

Figure 28 Fragment of matting that was used in wrapping the hide in bales (photo: J. Nientker (RCE)).

|

|

Figure 29 Folding method of the hides, as reconstructed by Stikker and Kleij (drawing: P. Kleij (RCE)).

|

Close scrutiny by Stikker (1988; 1991) and Kleij (1992b) revealed the characteristics of the cattle and of the processing the hides had been subjected to. Teats, for instance, were visible’and cows and bulls (or oxen) are represented in equal quantities, both old and young.

The cattle are small beef stock with a shoulder height of approximately 130 cm. The method of slaughtering varied, with most having a lengthwise incision at the throat. Others had a crosscut, which is characteristic, for instance, of Jewish and Islamic slaughtering. About one third of the hides displayed skinning cuts, some of them stitched up with botanical fibres. Stretching holes of 1 cm were cut approximately four cm from the edge and six cm apart. Several hides had a mark on the tail or right buttock, of which the meaning remains unresolved (fig. 30).

|

Figure 30 Several marks on tail or right buttock from bales AM-1/2.01.2.1 West and AM-1/2.01.3.1 East (drawing: N. Stikker/P. Kleij (RCE)).

|

The find is exceptional and knowledge of this raw material for leatherworking is not common. The expertise of the late W.B. van Herwijnen, formerly of TNO leather research institute in Waalwijk, proved invaluable. Author of a book on leather technology in the 1950s (van Herwijnen 1956), Van Herwijnen had been involved throughout his career in the quality assessment of leather from different sources and of tanning processes. He assessed the Aanloop Molengat hides as being of mediocre but varying quality. The preparation and tanning processes had not been meticulous. Skinning and cropping had been done roughly. Graining, a lengthy process of removing the hair with lime or flowing water, cleaning the inner side and curing the outer side with dog or bird excrement to make them supple, had left occasional patches of black or dark red hair. The inner and outer surfaces were well-tanned, but the interior was not. As a consequence, many hides split. The hides had been tanned with botanical tanning agents, coarsely diffused in water. The product suggests simple tan pits with a mix of oak, horse chestnut and chestnut barks as tanning agents, possibly enriched with mimosa or sumac. Long exposure to seawater has partly reversed the tanning process. Stretching holes indicate the final flattening, cleaning and possibly greasing of the sheets, but are cut irregularly.

The leather should be considered half-finished, to be curried (and possibly re-tanned) on arrival. Despite the varying quality of the individual sheets, the overall composition of the bales seems to be uniform (Kleij 1992b, 39). This indicates that production was dispersed and the shipment was gathered and purchased through a middleman.

The leather industry and commerce in the Low Countries processed hides not only from local tanneries, but also from Scandinavia, Germany, England, Spain and (from the early 17th century) Africa and America (Baart 1977, 69-71). On the basis of texture, grain, size and tanning, Van Herwijnen assumed a provenance from southern Europe, more specifically Spain. South America is another possibility (Kleij 1992b, 40). During the years 1630-1650 Amsterdam boasted a lively trade in ‘West-Indian’ (Southern American) hides.

In order to try and establish the breeding and provenance (Lenstra 2009), six samples of cattle hide were submitted for DNA research in 2011. They included material to which hairs adhered. The samples were examined by F. Welker using the facilities of NCB Naturalis (Welker et al. forthcoming). Only low concentrations of human DNA were found, and it is unclear whether these are contemporary or a recent contamination.

The fibres used to stitch the cuts and the matting in which the leather was packed were studied to identify the plant species used. The fibres derived from woody species or bark, possibly alder or willow, which are very common species. The matting possibly derived from broad-leaved cottongrass (Eriophorum latifolium), which is native to raised bogs and has not previously been identified as packing material (Brinkkemper & Joosten 2012; HyperlinkBrink). The outermost layer of cells (epidermis) was too poorly preserved to allow certain identification. Cottongrass occurs in large parts of Europe, and since the identification is uncertain, no inferences can be made regarding the origin of the bovine hides.

Textiles, with lead cloth seals

A total of 101 lead cloth seals have been found. Most were discovered in a wide spread in the excavation squares southeast of the wreck mound; a single one was found in the southwestern trial trench of 1985. This first seal comes from Mons in Hainaut and is provisionally interpreted as marking cloth of ordinary quality (Maarleveld 1988). On hindsight the seal is not as representative as then assumed. Only one other ‘Mons’ seal has shown up, as against 26 from Leiden, three from Delft, and ten from Hondschoote in the ‘Westhoek’ of Flanders (fig. 31). This means that the most important production centres of the Republic and of the Spanish Netherlands are represented. Another 16 cloth seals remain unidentified, whereas 44 merchant marks refer to individual merchants.

|

Figure 31 Lead cloth seals from (from left to right) Leiden, Delft, Hondschoote and Mons (photo: T. Penders(RCE)).

|

Frank van Deijk, who specialises in Leiden industry, undertook a study of these objects from that perspective. The collection is presented here for reference, without individual marks having been explored in full (HyperlinkDeijk). It must be assumed that the seals were attached to cloth that had been packed and stowed in the hold, on top of the heavy and more durable cargo and which decayed more or less on site, rather than being swept away with the ship’s upper parts.

A small cloth sample, enclosed in a seal from Delft, is the only textile that remained. Cloth seals are small, and many may have gone unnoticed in the excavation of shifting sands. The number of seals suggests that they represent a considerable shipment, but this is hard to assess. It is also impossible to say where exactly the bales were stowed, or whether the bales from the Northern Netherlands were stowed together or separately from the consignments that left fewer traces.

Leiden’s wool-based textile industry has been fairly well studied (Posthumus 1939; van Deijk 1993). Since the 1580s, it was organised in large corporations (neringen) that saw to the production of a specific kind of fabric. Each had its own type of cloth seal. Of the Aanloop Molengat seals, 26 were issued by the saainering, which was Leiden’s main trade until 1660. There is a striking similarity with woodcut images of seals and stamps in the organisation’s 1594 by-laws. In combination with other evidence, it is certain that all seals with the inscription LEYDS GVET (Leiden cloth) must originally have been attached to either ‘saye’ (saai) or ‘grosgrain’ (grein or grogrein). Both are non-felted fabrics. Saye (or serge) is woven in a twill pattern (keper) from strong worsted (kamgaren). Grosgrain is a plain woven fabric with a ribbed appearance as a result of the weft being thicker than the warp. In Leiden grosgrain, the warp is twined. The wool for both products was obtained from Scotland, Pomerania and Holland.

Unlike many of the merchant seals, the Leiden saainering seals have one pin. Although this does not show in the published photographs, the almost identical seals from the Wittenbergen wreck in the Elbe have two pins (Bracker 1986). This corroborates their 16th-century dating (Stanek 2011). Double-pin seals were prevalent up until 1593. A 1594 by-law made single-pin seals the norm (Posthumus 1912, 238). The dies used for the Aanloop Molengat seals show variations that are hitherto unknown. The obverse shield normally has a round base, but here a more Renaissance-style shield also appears. Varieties of the reverse are more significant. In 1630 it became obligatory to mark the year.[7] The most common reverse consistently includes the date 1635, divided either side of a rampant lion (see fig. 43). The imprint of another die has the inscription ‘[an]no 16[..]’, the year being unclear. The third type probably also had a date.

It is not just the type of seal, however, which primarily indicated the type and quality of the fabric produced under control of the saainering, but rather their number (up to five) and spacing. A saye fragment with three seals, found in Amsterdam, illustrates the system (Baart 1988). Luckily, there are some additional clues, for instance counter-stamped tally marks that indicate the length in Brabant ells (69.8 cm). Each cloth received one tally mark only. Six seals have a mark for 36 cubits (approx. 25.13 m). The by-laws give standards for gross length, before finishing would cause shrinkage. The closest match is for herensaai, the top-quality product. This fabric would have had about 20 threads per cm width. Other counter stamps give an indication of grades of quality: L stands for first quality (three seals), X for second quality (two seals). One seal is special. It also bears a ‘split eagle’ mark (fig. 32). The eagle marks of the Leiden saainering point to different qualities of blue woad dye as a basis for black (one eagle), light violet (split eagle) or deep violet (double eagle). They were used for herensaai and grein/grogrein exclusively and thus support the conclusion on the basis of the tally marks (Posthumus 1914, 60 (par. 21), 69, (par. 64), 70 (par. 80), 75 (par. 101); Posthumus 1939, 1176).

|

Figure 32 Split eagle tally mark on a Leiden cloth seal AM-H-28, indicating the light-violet color of the fabric. A similar split eagle was found on a cloth seal from Delft (photo: T. Penders (RCE)).

|

|

Figure 33 Sample of fabric (AM-1993-65-5), twill, woven from worsted. Length is 1.5 cm (photo: T. Penders (RCE)).

|

The Delft seals can be discussed more briefly. A sample of fabric was taken from one of these. Again we find twill, woven from worsted (fig. 33) (Nientker 2011 HyperlinkNientker). This means we are dealing with Delft saai. Its production started in 1595-96, when ten Leiden drapers moved to Delft, much to Leiden’s chagrin (Posthumus 1912, 249-271, 273-274). High-performance liquid chromatography shows that the dye used was derived from woad or indigo, madder and a third, unidentified colouring agent (at a very low concentration). New, the fabric was probably purple (van Bommel & Joosten 2012 HyperlinkBommelJoosten). Interestingly, another Delft seal has a ‘split eagle’ counter stamp. According to regulations from the 1640s, Delft saai had to be dyed in Leiden. Earlier rulings remain unclear, but the present find seems to indicate that this had been standing practice.

The Hondschoote textile industry has been the subject of one of the classic studies in the French Annales School of socioeconomic history (Coornaert 1930). Like Leiden, Hondschoote produced cloth of different qualities. Both were at the peak of their production at the time of the Aanloop Molengat wreck (Deyon 1972, 26). In both cities, the emphasis seems to have been on different qualities of sayes and regulations are particularly comprehensive for the highest quality of doucques and sayes de seigneurs (Coornaert, 216ff.). Although it is therefore quite possible that the Hondschoote consignment matched the quality of the herensaai from Leiden, we cannot establish the connection between the actual lead cloth seals and the quality they represent. By comparison with Leiden and Hondschoote, the industry of Hainaut – and specifically that of Mons – has been less well-studied, as a major part of the relevant archives were destroyed in May 1940 (Verriest 1942a; Verriest 1942b). Assumptions about the type of fabric represented by the Mons seals are therefore hard to corroborate.

The cargo contained textiles produced in urban industries in Holland, Flanders and Hainaut. It is not known how much or whether these were packed together or separately. What is known is that the shipment included at least six, but more likely ten, pieces of herensaai produced in Leiden. Four were certainly of first quality (including a light violet one), another four were presumably first quality, and two were of second quality. It can be assumed that all these pieces were dyed, which was compulsory for herensaai. After being folded into a square and placed in a large heated press, the sides were stitched together using a silk thread. There was also purple saai that had been produced in Delft and dyed in Leiden, and Hondschoote textiles that may well have been sayes of similar quality. It is no more than an assumption that the cloth from Mons was ordinary.

Ivory

A large elephant tusk was found firmly cemented to the top and side of the iron bulk, close to its northern corner (at 21.5 m). The concretion features the impressions of at least two more tusks (fig. 34). The tusk has a diameter of about 13 cm at its base, and a length of more than 1.15 m (fig. 35). Only large African elephants have tusks of that size (Rijkelijkhuizen 2011, table 2).

|

Figure 34 In situ sketch of the elephant tusk (tand) and impressions (afdruk) around it (from: Divereport Maarleveld 10-07-1992).

|

Since its establishment in 1621, the West India Company was the main importer of ivory to the Dutch Republic (Rijkelijkhuizen 2011, 228). Elephant tusks were obtained from the Gold Coast in West Africa, present-day Ghana, particularly at Fort Nassau and Elmina. The Dutch did not hunt elephants themselves, but depended on the African inhabitants to bring tusks from far afield, perhaps even from East Africa (Rijkelijkhuizen 2011, 230). Ivory was used by craftsmen in the Dutch Republic for all sorts of purposes – lice combs, knife handles, toys, items for personal care, knitting and needlework items, parts of musical instruments, dice, fans, brushes, needles, piano keys, buttons, syringes, boxes and inlay for furniture and weaponry (Rijkelijkhuizen 2009, 427) – and was sold at one guilder a pound (den Heijer 1997, 135). It was also exported, for instance to Asia, where large African elephant tusks were highly valued.

Quicksilver, in bottles?

During the excavation, small beads of mercury were occasionally found, rolling in hollows in the sand, in the grooves of wrought-iron or adhering to brass pins. A few drops were collected (fig. 36), most of them together with pins. Although there was some apprehension with regard to the presence and handling of mercury (and lead), this did not lead to a precautionary regime in the excavation. Protective clothing and dive suits were evidently worn, and common sense in handling was relied upon. Although only small amounts were registered, these were found so dispersed that they must represent a considerable shipment.

Mercury or quicksilver is occasionally found in historical wrecks. It is relatively rare and expensive. Mined at various places in Europe, such as France, Austria, Hungary, Poland, Spain and the Balkan peninsula, it was used in thermometers and barometers, in making mirrors and felt hats. Large amounts were needed in metallurgical processes, notably the extraction of silver. Although it was traded over long distances, transport of the liquid and very heavy metal (density of 13546 kg/m3) was problematic.

In an 18th-century Spanish wreck off the Dominican Republic, a large consignment of mercury has been discovered in small casks packed in cases (Peterson 1979). Evidently, various containers were tried, as is reflected in successive directives of the Dutch East India Company VOC (Green 1977). In the 17th century it was shipped to Asia, probably to be used for the gilding of objects (Sténuit 1977, 441-443). It was also taken on board as part of the ship’s pharmacy (Gawronski 1996, 212). In archaeological literature, Bellarmine jugs are referred to as the most common containers for mercury in the Aanloop Molengat period (Green 1977, 481). No sherds of such jugs were found. The only possible container elements in the assemblage are lead screw caps (fig. 37). Twenty-three caps were found, consisting of a lower part, which was attached to a glass bottle, and an upper part, which could be screwed onto the lower part. The caps have a diameter of 1.8 to 2.3 cm and a height of 2.0 to 2.4 cm. XRF measurements revealed mercury inside these caps, at the bottleneck (van Os 2011 HyperlinkVan Os). This mercury may have attached itself to the caps in the same way as it did to pins, but it would be more logical to assume that the mercury was stored and transported in glass bottles with lead screw caps. The same suggestion is made in relation to bottle caps and neck reinforcements of similar type in the assemblage from the Lastdrager that wrecked in 1653 (Sténuit 1977, 440).[8] It is notable that one of the 1636 VOC regulations recommends the use of square bottles in a case (Green 1977, 481). Although some glass was found, it is too little for reconstructing bottle form and size. Square capped storage bottles (kelderflessen) are known in sizes varying from 235 ml to 1.8 l or more (Henkes 1994, 236-244). If the caps sat on bottles of 1.2 litres, 23 bottles would account for approximately 375 kg of mercury. It is likely, however, that the 23 caps represent only a fraction of the total number of bottles.

|

Figure 37 Screw cap with a sherd of glass. Although similar caps are generally referred to as pewter, these caps are 90 to 97% lead. Diameter cap is 3 cm (photo: T. Penders (RCE)).

|

Spices and seeds

In dismantling the bales of leather, hundreds of impressions of seeds were visible in the iron concretion, and a few uncharred round seeds could be recovered (Kleij 1992b, 17). The seeds had been hermetically sealed in between the hides and were therefore well preserved. The botanical remains were analysed by M. Manders and W.J. Kuijper at the Institute for Prehistory, Leiden University.

The spherical seeds are the most conspicuous (fig. 38). They are identified as black pepper (Piper nigrum). As the outer skin is lacking, white pepper is another possibility. The largest peppercorns are 4.5 mm across (Manders 1992, 43).

Impressions of cereal remains, in particular wheat grains (Triticum aestivum), were visible in the iron concretion. Husks of wheat grains were found in between the hides (Manders 1992, 43-44). In addition, two seeds of corn cockle (Agrostemma githago), a crop weed that is notorious for being poisonous, were found among the seeds.

The presence of pepper, an expensive spice, could indicate a shipment for trade. However, the combination with cereal remains in almost negligible quantities could also mean that pepper and wheat were taken on board for consumption, and only ended up with the cargo as a result of the wrecking process.

Brass pins

From 1985 to 1999, a total of 719 pins were found in excavation. Their length varies from 2.4 to 7.8 cm, their diameter from 0.4 to 1.2 mm and their heads from 1 to 3 mm (n=179). Several groups can be distinguished: small pins of 2.4-2.7 cm, pins of 3.4 to 3.9 cm, pins of 4.0-4.5 cm, pins with a length of 5.4-6.0 cm, pins with a length of 6.8-7.2 cm and large pins of 7.5-7.8 cm (Chart 6, fig. 39). Interestingly, four types of pins are mentioned in a deed from 1590 (van Dillen 1929, nr. 789).

Chart 6 Length distribution of the pins.

The pins were discovered throughout the excavated area in the southeast. Of the 490 pins found there, 11.4% came from section A, 35.3% from section B, 8.4% from section C, 20.2% from section E, 9.0% from section F and 7.4% from section J. A concentration of finds occurs in the south and east corners of the frame. However, pins are light and may easily have been moved around with moving sediment or by airlift, so a definite stacking location for the brass pins cannot be derived from this spread.

The pins are made of drawn brass wire. At one end the pins have a sharpened point; at the other a twisted pinhead is attached. The pinpoints are quite sharp; sometimes one side of the pin is sharpened over a longer surface than the other side. The pinhead mostly consists of two coils, usually twisted to the right, and occasionally to the left (fig. 40). Some pins have a thickened upper end instead of a twisted pinhead, but nevertheless seem to be complete (Raymakers 1996, 20).

Pins with a twisted head were manufactured from the beginning of the 16th to the first half of the 19th century. The Low Countries were an important exporter and during the first half of the 16th century most of the pins used in England were imported from there (Harsman 2010, 48). Amsterdam, Bremen and Gloucester were the centres of 17th-century pin-making (van Dillen 1929, nr. 789). In 16th and 17th-century Amsterdam, pin-making was typically a domestic industry, in which all family members were involved. In the second half of the 17th century, the Nieuwe Werk quarter (later called de Jordaan) had seven pin-makers’ alleys (Oldewelt 1946, 158-160; Baart 1977, 135). In later centuries, there was a trend towards the establishments of workshops (Baart 1977, 133).

A pin may be a simple artefact, but the process of pin-manufacturing was an elaborate one. First, the brass wire was cleaned and then drawn into the thickness required, cut to length and sharpened. Another (finer) wire was twisted to form the head. The heads were attached to the shanks by being struck with a heavy ram. The pins were then cleaned or yellowed, tin plated, polished and stuck into papers before being offered for sale (Philips 1821, 299-301).

From the 15th to the 18th century, pins were a luxury and expensive (Raymakers 1996, 27). In the 18th century, production processes changed. Pins were made in factories and became less expensive, but their appearance remained exactly the same. Adam Smith uses pin-making in his famous Wealth of Nations to show how productivity rises through division of labour, and describes the process in detail. To make one pin, eighteen actions had to be performed, which were done by ten people. One person performing these steps alone could make 20 pins a day. The ten people together could make 48,000 pins a day (Smith 1776, 5).[9]

Pins were used in handwork and needlework, for making clothes and hats, and for fastening clothes. In early modern times, sleeves and bodices were pinned to the rest of the clothes. According to Van Deijk it is unlikely that the pins were used for the textile shipment. We must therefore assume that they were packed separately. Paper packages as described in literature are likely to have been packed in larger packages, but we have no archaeological evidence as to how, and they barely contribute to the overall weight of the cargo. The trade in pins is documented in other ship finds such as BZN 2 in the Texel Roads (built 1662-1665, wrecked around 1670), where pins, rolls of brass thread and lead cloth seals were found (Vos 2012). A later example is the Amsterdam that ran aground near Hastings in 1749 (Gawronski 1986, 46).

Cannon balls in cases